8

years of experience

12

projects

5

granted patents

15

pending patent applications

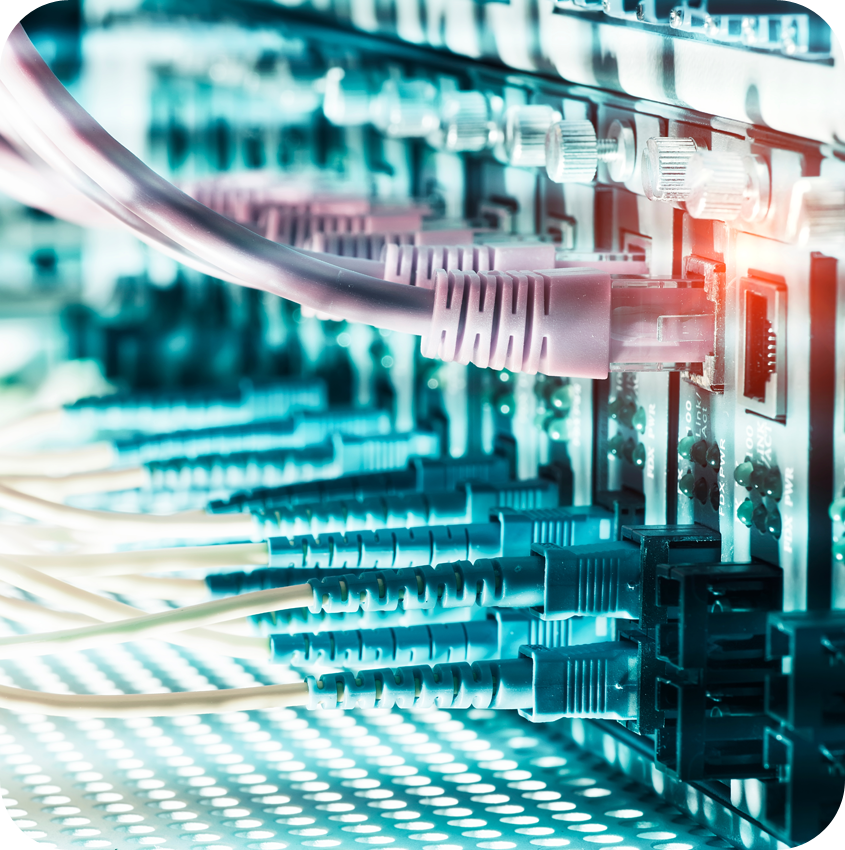

Polish Center for Photonics

and Fiber Optics

The Polish Center for Photonics and Fiber Optics (PCFS) provides consulting, training and information services. It supports the transfer of photonic technologies and all the accompanying tasks. It conducts research, development work and takes care of disseminating the achievements of Polish optical fiber photonics.

We operate at the interface between science and business, and our goal is to implement Polish innovative photonic solutions, support scientists and entrepreneurs, and build a strong Polish photonics sector.

Polish Fiber Optics.

Discover breakthrough solutions

We encourage you to download our catalog "Polish Fiber Optics. Breakthrough innovations as a path to the development of a modern economy." We present here specific fiber optic solutions dedicated to various industries.